Magnesium Die Castings for Automotive and Non – Automotive Applications

Magnesium Die Casting has many Major Advantages such as :

weight reduction

excellent machine-ability

recyclable

long die/tool life

low density

high stiffness

impact strength and dent resistant

dimensional stability

Cast Magnesium Alloys

| AM60 A | AM60 B | AZ91 A | AZ91 B | AZ91 C | AZ91 D | AZ91 E | |

| Al | 5.5 – 6.5 | 5.5 – 6.5 | 8.3 – 9.7 | 8.3 – 9.7 | 8.1 – 9.3 | 8.3 – 9.7 | 8.1 – 9.3 |

| Mn | 0.13 max. | 0.25 min. | 0.13 min. | 0.13 min. | 0.13 min. | 0.15 min. | 0.17 – 0.35 |

| Si | 0.5 max. | 0.10 max. | 0.50 max. | 0.50 max. | 0.30 max. | 0.10 max. | 0.20 max. |

| Zn | 0.22 max. | 0.22 max. | 0.35 -1.0 | 0.35 – 1.0 | 0.40 – 1.0 | 0.35 – 1.0 | 0.4 – 1.0 |

| Fe | 0.005 max. * | 0.005 max. ** | 0.005 max. | ||||

| Cu | 0.35 max. | 0.010 max. | 0.10 max. | 0.3 max. | 0.10 max. | 0.030 max. | 0.015 max. |

| Ni | 0.03 max. | 0.002 max. | 0.3 max. | 0.03 max. | 0.01 max. | 0.002 max. | 0.0010 max. |

| Other | 0.003 max. (total) | 0.30 max. | 0.30 max. | 0.3 max. (total) | 0.02 max. (each) | 0.01 max. (each) | |

| Other | 0.30 max. (total) | ||||||

| Mg | bal | bal | bal | bal | bal | bal | bal |

*If Fe content exceeds 0.005% then the permissible Fe to Mn ratio will not exceed 0.021

**If Fe content exceeds 0.005% then permissible Fe to Mn ratio will not exceed 0.032

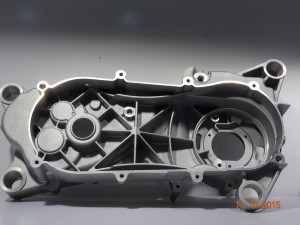

Some Typical Applications for Magnesium Die Castings:

transmission casing,engine blocks,steering wheel,structural castings for power train components,wheels,interior trim parts

chainsaw body,lawn mower,portable saws,drills,grinders

cameras,computers,cell phones

equipment housings,luggage,cases

brackets,housings,covers

tools

bakery racks

bicycle parts

Galvotec can produce just about any Magnesium Die Casting to customers specifications or requirements

Send us your engineering drawings and we can supply you with a budgetary quotation

Please Contact Us: For Magnesium Die Casting

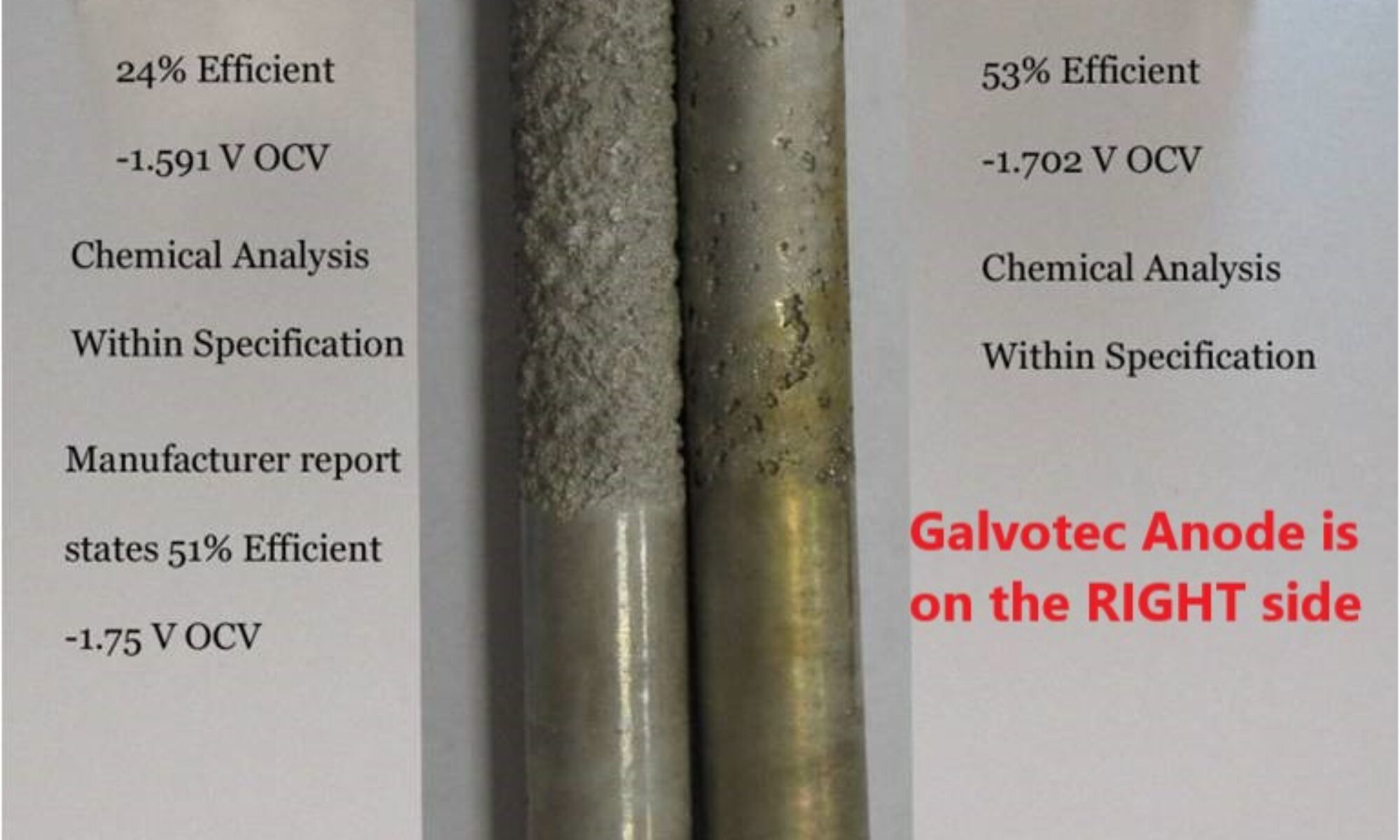

Premium Magnesium Extrusions, Magnesium Die Castings, Magnesium Sacrificial Anodes, and Magnesium Products